Making Indoor Scale Models Perform

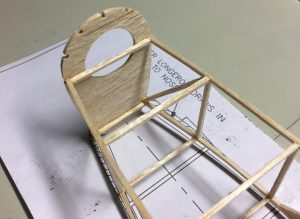

Rubber powered flying scale models built from the popular Golden Age Reproductions plans & kits can deliver fantastic flight performance.

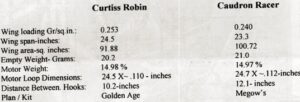

Several years ago a top New England (US) flyer built a couple of popular Golden Age Reproductions flying scale models. One was the Megow 20″ span Caudron C460 Racer (plan available here) and the other a 25″ wingspan Scientific Curtiss Robin. They were fabulous flyers with flight times of 80sec to 2min duration indoors.

Being an engineer, the author documented the key specifications for his models – weights, wing area, motor dimensions, etc. He also charted the empirical results from a number of flights on each model.

The analysis compares the performance of the two models and draws some insightful conclusions relative to high wing vs. low wing configuration, the effects of drag and wing undercamber, etc.

There’s lots of great information in this brief analysis for both experienced and newer modelers. Aim to replicate these specifications and you’ll have a great flying rubber scale model.